CEO Jim Farley announced today, from Ford’s Louisville plant, a bold investment plan into affordable EVs to tackle Chinese rivals.

Farley introduced the speech with the ‘Ford Universal EV Platform,’ a project three years in the making, to streamline EV production and lower costs. The first vehicle on this platform will be a mid-size pickup truck, available for 2027, starting at $30,000.

He described the perfectly capable car: “…More spacious inside than the RAV4 [USA’s current best-selling car], but it will have a ‘frunk’ and it will have a whole pickup truck bed behind it.

“It will be faster than our Mustang Twin-Turbo … It will offer fast charging, it will have amazing range. It will power your house for six days … And we’re gonna start this vehicle at $30,000.” Those are huge promises.

Ford aims to challenge Chinese rivals – with Farley specifically mentioning companies such as BYD – claiming “they’re all coming for us,” and “we needed a radical approach … to create an affordable vehicle that delights customers in every way.

“And we need to do it with American workers”.

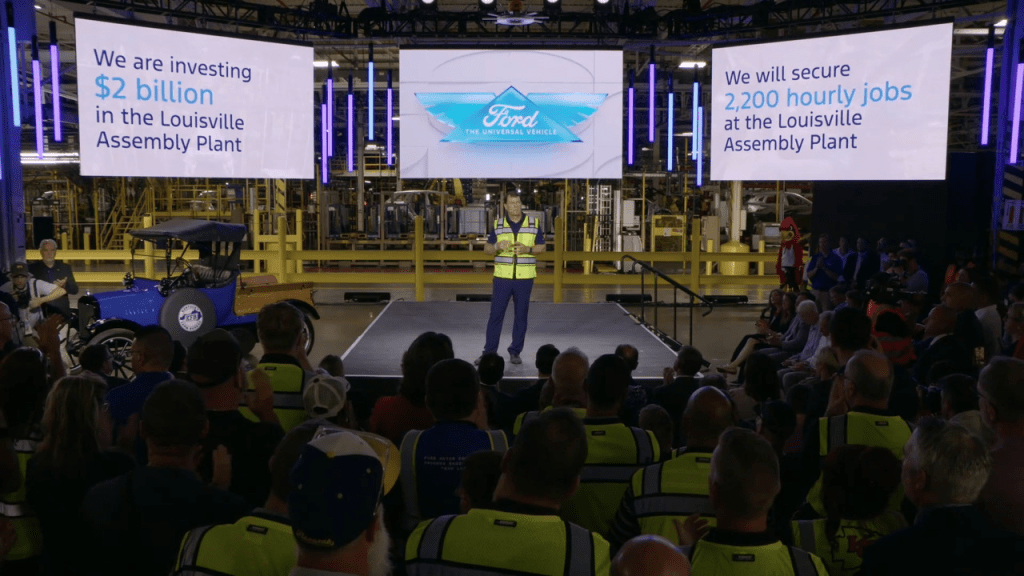

Investments included $2 billion into the Louisville plant and $3 billion into the Blue Oval Michigan battery plant, creating 4,000 US jobs. Ford’s challenge is taking on battery production themselves, rather than importing from Japan and South Korea at a lower cost.

Doug Field, Ford’s ‘Chief EV, Digital and Design Officer’ referenced Tesla and Rivian as innovative startups, and drew from Henry Ford’s conclusion to the Model T: “The best in our field … dying for a chance to challenge convention.

“Just like the Model T, this innovation is gonna be how we deliver affordability, and as Jim said, a sustainable project. Not a charity case. Not a compliance project.”

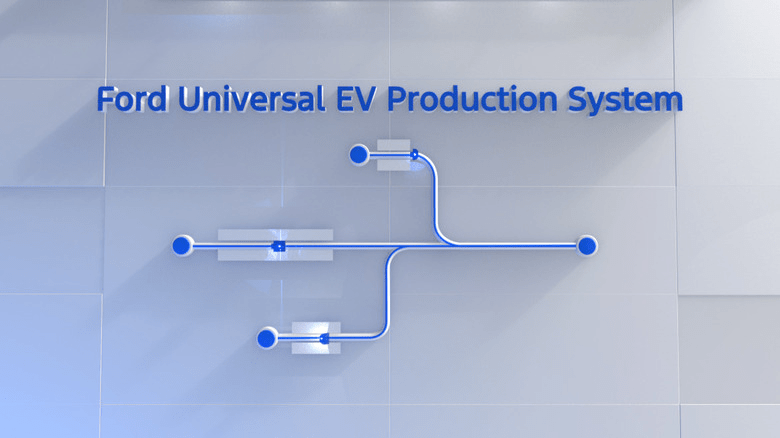

Rather than using a single production line, this next generation of EVs will be constructed in a ‘tree formation,’ streamlining production line activities.

Bryce Currie, Vice President of Americas Manufacturing, explained benefits to production workers included:

- 84% less reaching over the fender.

- 63% less sitting in the vehicle to install parts.

- Overall, the process will be 40% quicker than current Louisville plants.

- 20% fewer parts, 50% fewer cooling hoses and connections, and no pop clamps.

Other benefits included cutting out 4,000 feet of wires and two-thirds of the welding to reduce time and effort for workers, be more cost-effective, and ultimately deliver a quality product in less time.

As for the $30k pickup: parts were teased during pre-recorded segments, but no concept, model, nor rendering were ever shown in full. Given the 2027 deadline for full release, we expect to see previews within the next six months.

Leave a comment